OCP2185技术方案资料:

OCP2185_EN-datasheet.pdf

OCP2185_EN-datasheet.pdf

6~30Vin@8W Ultra low cost and high efficiency of small LED driver solution OCP2185.rar

6~30Vin@8W Ultra low cost and high efficiency of small LED driver solution OCP2185.rar

General Description of OCP2185

The OCP2185 is a step-down DC/DC converter designed to drive LEDs with a constant current. The device can drive up to 8 LEDs, depending on the forward voltage of the LEDs, in series from a voltage source of 6V to 30V. Series connection of the LEDs provides identical LED currents resulting in uniform brightness and eliminating the need for ballast resistors. The OCP2185 switches at frequency up to 1MHz. This allows the use of small size external components, hence minimizing the PCB area needed.

Maximum output current of OCP2185 is set via an external resistor connected between the VIN and SET input pins. Dimming is achieved by applying either a DC voltage or a PWM signal at the CTRL input pin. An input voltage of 0.4V or lower at CTRL switches off the output MOSFET simplifying PWM dimming.

Features of OCP2185

◆ LED driving current up to 1A

◆ Better than 5% accuracy

◆ High efficiency up to 98%

◆ Operating input voltage from 6V to 30V

◆ High switching frequency up to 1MHz

◆ PWM/DC input for dimming control

◆ Built-in output open-circuit protection

Applications of OCP2185

● MR 16 lamps

● General illumination lamps

Pin Configuration of OCP2185

Typical Application Circuit of OCP2185

OCP2185 electrical test parameters:

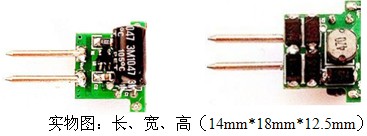

Application of MR16 physical map of OCP2185

Application information of OCP2185

OCP2185 Operation

In normal operation, when voltage is applied at +VIN, t he OCP2185 internal switch is turned on. Current starts to flow through sense resistor R1, inductor L1, and the LEDs. The current ramps up linearly, and the ramp rate is determined by the input voltage VIN and the inductor L1.

This rising current produces a voltage ramp across R1. The internal circuit of the OCP2185 senses the voltage across R1 and applies a proportional voltage to the input of the internal comparator.

When this voltage reaches an internally set upper thres hold, the internal switch is turned off. The inductor current continues to flow through R1, L1, the LEDs and the schottky diode D1, and back to the supply rail, but it decays, with the rate of decay determined by the forward voltage drop of the LEDs and the schottky diode.

This decaying current produces a falling voltage at R1, which is sensed by the OCP2185. A voltage proportional to the sense voltage across R1 is applied at the input of the internal comparator. When this voltage falls to the internally set lower threshold, the internal switch is turned on again. This switch-on-and-off cycle continues to provide the average LED current se t by the sense resistor R1.

DC Dimming(OCP2185)

The CTRL pin can be driven by an external DC voltage (VCTRL), to adjust the output current to a value below the nominal average value defined by RSET. The LED current decreases linearly with the CTRL voltage when 0.5V ≤ VCTRL≤ 2.5V. When the CTRL voltage falls below the threshold, 0.4V, the output switch is turned off which allows PWM dimming.

Note that 100% brightness setting corresponds to VCTRL = VREF, nominally 2.5V. For any voltage applied on the CTRL pin that is higher than VREF, the device will not overdrive the LED curr ent and will still set t he current according to the equation VCTRL = VREF.

.

PWM Dimming(OCP2185)

LED current can be adjusted digitally, by applying a low frequency Pulse Width Modulated (PWM) logic signal to the CTRL pin to turn the device on and off. This will produce an average output current proportional to the duty cycle of the control signal. In particular, a PWM signal with a max resolution of 10bit can be applied to the CTRL pin to change the output current to a value below the nominal average value set by resistor RSET. To achieve this resolution the PWM frequency has to be lower than 500Hz , however higher dimming frequencies can be used, at the expense of dimming dynamic range and accuracy.

Typically, for a PWM frequency of 500Hz the accuracy is better than 1% for PWM ranging from 1% to 100%.

Reducing output ripple of OCP2185

Peak to peak ripple current in the LED(s) can be reduce d, if required, by shunting a capacitor C2 across the LED(s) as shown already in the circuit schematic. A value of 1μF will reduce the supply ripple current by a fact or three (approx.). Proportionally lower ripple can be achieved with higher capacitor values. Note that the c apacitor will not affect operating frequency or efficiency, but it will increase start-up delay, by reducing the rate of rise of LED voltage. By adding this capacitor the current waveform through the LED(s) changes from a triangular ramp to a more sinusoidal version without altering the mean current value.

Capacitor Selection of OCP2185

The small size of ceramic capacitors makes them ideal for OCP2185 applications. X5R and X7R types are recommended because they retain their capacitance over wider voltage and temperature ranges than other types such as Z5U. A 2.2μF input capacitor is sufficient for most intended applications of OCP2185; however a 4.7μF input capacitor is suggested for input voltages approaching 30V.

Diode Selection of OCP2185

For maximum efficiency and performance, the rectifier (D1) should be a fast low capacitance Schottky diode with low reverse leakage at the maximum operating voltage and temperature. The Schottky diode also provides better efficiency than silicon PN diodes, due to a combination of lower forward voltage and reduced recovery time. It is important to select parts with a peak current rating above the peak coil current and a continuous current rating higher than the maximum output load current. In particula r, it is recommended to have a diode voltage rating at least 15% higher than the operating voltage to ensure safe operation during the switching and a current rating at least 10% higher than the average diode current. The power ra ting is verified by calculating the power loss through the diode.

Schottky diodes, e.g. SS14 or SS24, with their low forward voltage drop and fast reverse recovery, are the ideal

choice for OCP2185 applications.

Applications Information of OCP2185

Figure.9 Gives details about the PCB layout suggestion:

1 、 The capacitor C1 has to be placed as close as possible to VIN.

2 、 The sense resistor R1 has to be placed as close as possible to VIN and SET.

3 、 The D1 anode,the SW pin and the inductor have to be placed as close as possible to avoid ringing.

Keywords: ORIENT-CHIP OCP2185 OCP2185WAD ZXLD1350 ZXLD1360 ZETEX MR16PWM dimming function wall wash lights cast light lamps and other lighting circuit protectionLED driver LED constant current drive